How To Manufacture A Product In China

How To Industry A Product In Red china (without losing your shirt)? [Importer'due south Guide]

How To Manufacture A Production In China (without losing your shirt)?

Introduction to new production manufacturing

How to manufacture a production in People's republic of china? Unless you lot take done this professionally for years, information technology might be a very painful experience resulting in you 'losing your shirt!'

I take been working with companies in your situation for over 10 years, and this guide is just for you. It won't requite you a precise map, as there is no such matter. What it will give you lot is a alarm about the 3 major pitfalls you need to avert, and a series of 'best practices' the all-time companies follow.

Everything in this guide is written from the indicate of view of a startup or SME launching a new electromechanical product. Goose egg hither is outside of your reach (or 'just for big companies').

But wait… isn't everybody leaving People's republic of china and manufacturing somewhere else these days?

Big companies that sell a lot in the United states of america are moving some of their mature productions to Vietnam, Bharat, Malaysia, Thailand, and then on. That'south correct.

Nevertheless, if you desire to develop a new mechanical and/or electronic product fast and without unnecessary hurdles, you lot volition very probably demand to practise the manufacturing in China for several reasons:

- Y'all will be close to a broad range of component suppliers, surface treatment facilities, and so on,

- Tooling tin can be fabricated fast and (relatively) inexpensively,

- Human resources, and in particular expertise in different technologies & processes, seem unlimited,

- Cathay's infrastructure, and its network of service providers, is unparalleled in Asia.

Keep reading the guide or jump to the section you prefer direct by using the links in the table of contents below:

![Download How To Manufacture A Product In China? [Importer's Guide] Download How To Manufacture A Product In China? [Importer's Guide]](https://qualityinspection.org/wp-content/uploads/2020/01/cta.png)

Start: You need to notice and vet the RIGHT supplier

This guide is written to assist y'all manufacture a new product in China without running into problems that will harm your business organisation and event in products that don't meet your expectations. The initial building block for good results is finding and vetting the right supplier.

If you're still at that stage, you will do good from get-go reading these blog posts about vetting a suitable new supplier or, if you prefer your content in audio form, you can listen to our podcast serial on vetting new suppliers, likewise.

The three deadly mistakes that will hurt your ability to manufacture a new product in China effectively

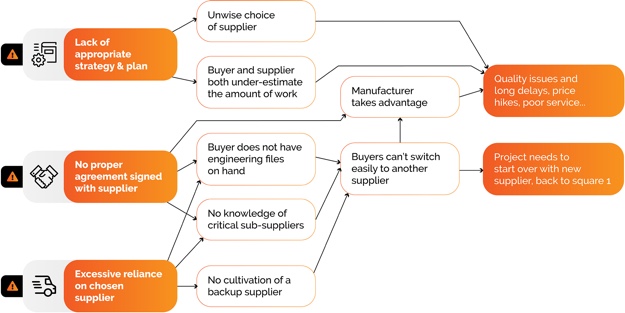

This department could have been entitled "The Domino Issue of Cathay Manufacturing". Making 2 or 3 critical mistakes at the showtime of a new production development projection volition usually trigger a sequence of other serious problems.

I looked at the many millions of dollars wasted on the Coolest Cooler (a Kickstarter project that failed miserably) recently, and I discussed this topic with a few people who confirmed my observations:

The same types of issues tend to plague companies who are wondering how to manufacture a product in China, and they are usually caused by a few mistakes made early in the procedure. Hither is the way it usually unfolds.

Deadly mistake i:

No appropriate strategy & plan

This oft leads companies into the hands of the wrong type of supplier. Here are a few examples:

- Working with an ODM manufacturer considering they already take relatively similar products… with the risk of being their source of ideas for their own new products

- Working with a trading company that might not have much control over what happens at the factory

- Working with a large organisation that volition never put their all-time resources on your (tiny) project

- Working with a manufacturer that doesn't even have the right engineering competencies

Many companies have come to united states after getting frustrated by a bad-fit supplier. And we noticed that this original error was usually at the source of many other problems:

- Excessive confidence in one supplier, and lack of a backup supplier, which becomes a huge problem when the electric current relationship needs to exist concluded (every bit I will cover later on). For anything but a pocket-size project, cultivating a fill-in is important. Fifty-fifty if you don't get 100% production-ready, they should exist at to the lowest degree halfway there.

- Ignorance of the wide gap between R&D (a few prototypes of the production made with components from random suppliers) and NPI (a certified product, ready tooling, set production processes, set up testing stations, qualified suppliers, and the ability to transition from product development to mass production smoothly). Since it is ignored, information technology is disregarded… even though bridging this gap might take six months of difficult work!!

- Since the buyer has no realistic vision of what it will take to get to a successful (i.due east. by and large trouble-free) mass production run, they make three serious mistakes:

- Trusting the supplier's rosy projections (which oft turn out to exist massively over-enthusiastic) without requesting a specific plan and challenging it. Aye, certain, it can send out in 4 months…

- Promising a go-to-market at an unrealistic appointment to eager retailers and/or crowdfunding backers, and delivering 6-xviii months late!

- Promising a certain product to the market and to investors, before the product design is really mature. What if finally, you need to change a material to make information technology manufacturable at scale? Or a part of the software, to pass a certification?

- Some other common trap for starting time-time buyers is their impression that a 'sourcing amanuensis' will make the whole procedure easier. This is fine if the agent is paid for their piece of work and they follow a certain process. This becomes a huge problem in these cases:

- The "agent" handles everything and blocks advice between the buyer and the manufacturer. This is a huge no-no. The buyer needs to acquire from the process and see everything offset-hand.

- The "amanuensis" is paid a pct of the number of orders. This incentivizes them to human activity every bit the supplier's sales amanuensis, rather than watching out for your interest. Why? Because they will have to proceed the relationship going (fifty-fifty if the factory misbehaves badly) and get the orders shipped out (even if there are quality issues), in lodge to go paid.

Deadly mistake 2:

No proper understanding was signed at the beginning of the relationship

There's so much to do when working out how to manufacture a production in China that a proper agreement is often set bated and forgotten… until the buyer starts to take doubts (or clear signs of misconduct). Brand no fault, though, it'due south essential! Here are a few key benefits information technology would provide:

- Get the supplier to commit to keeping the pecker of materials (i.e. the list of all components, with their sources and prices) open up to you. If you request this from the get-go, some manufacturers will accept.

- Get the supplier to recognize that all intellectual property developed is yours. Yes, it should be "normal", but in Red china, it is not…

- Have leverage in case the supplier misbehaves. This will utilise if you lot make the agreement enforceable in the state of the supplier. I'll suggest you read the first of this article on the Mainland china Law blog, as it points to many skilful resources on this topic. Many elements become into a practiced agreement.

The most of import is to do this at the very kickoff.

One time you have started working with a Chinese supplier, you accept invested some time, and they have fabricated some progress, they know you won't switch away from them. Proficient luck to become them to sign your agreement at that stage… it is frequently too late.

What happens in this case? It doesn't always happen, but the supplier might heighten prices. Or they might deliver poor quality. Or they volition take your tooling and/or products earnest when you kickoff to threaten them with penalties.

These situations have killed thousands of new product manufacturing projects. Don't be ane of these casualties. The solution is well-known and applicable to your situation with a scrap of adjustment.

Deadly mistake iii:

Excessive reliance on the chosen supplier

Since you lot tend to fall in love with a manufacturer and entrust your entire project to them, you neglect to accept any precautions.

(This is in addition to the absence of a proper agreement, and it compounds the furnishings I mentioned above.)

The near mutual symptoms of this mistake are every bit follows:

- The heir-apparent has no knowledge of the disquisitional component suppliers (or the factories doing disquisitional surface treatment such as plating, painting, and so on). This makes switching to a new supplier even harder, as everything has to be started over from scratch.

- No (micro)management of the engineering science piece of work. The buyer doesn't have the drawings, the schematics, and other non-recurring engineering deliverables. Again, moving away from the current supplier means starting over from scratch!

This is at the heart of what our company does, and many importers come up to u.s.a. for that kind of piece of work. Unfortunately, when they realize how footling information they take in their hands, and how bad their alternatives look, they sometimes decide that their only viable solution is trying to salvage their current supplier relationship…

This decision drives them to get even deeper into their hole. Sometimes they observe a manner to become some products to marketplace and get some oxygen. Oftentimes, though, they are digging their own projection's grave. When they have run out of funds and there is no articulate path ahead, information technology is oftentimes wiser to admit defeat.

Are YOU 'China-ready'?

A friend told me one time that many companies coming to Shenzhen or Shanghai to purchase products are not "Mainland china-ready".

Thousands of companies are formed every year to develop and brand new products, they are non "Cathay-set", and they have the confidence to become at it without proper communication and support.

This is like attempting to learn how to make a parachute after jumping from a airplane. Ownership off-the-shelf products can already be challenging. Developing a new product from scratch is orders of magnitude harder and riskier. Doing it without first spending time to sympathize the playbook about how to manufacture a product in China is really brave…

What are some signs that you may not be "China-ready"?

- You run into with a potential supplier and they go out of their way to brand you feel welcome. The boss takes you out to a gorgeous dinner. You are impressed. Yet, all this is only the standard way of making a sale in Prc. Information technology does not mean they will care for you lot as a VIP customer all throughout the human relationship.

- You feel confident nigh the factory. "They work for Microsoft" sounds skillful, simply it ways nada until you lot have tangible proof of information technology. "They are on the Apple tree supplier list" is better and can be verified, only it won't guarantee anything. I know this beginning-hand — we have seen a big and famous group working for Apple cheating small importers repeatedly.

- Y'all make all sorts of assumptions that are very, very dangerous. I wrote a list of 21 mutual assumptions before, and here are a few examples:

- You call back an NDA is an NDA, and y'all can use the template you accept been using in your home country. Actually, it volition be useless in China.

- You find Alibaba.com. You believe all the data yous read at that place is truthful. Yous feel a "Gold Supplier" badge ways they are safer than the others. All wrong.

- The manufacturer says they will make the tooling. You assume that tooling fabrication (and all the sensitive intellectual holding that goes with it) will exist done inside their four walls. You lot assume it will be yours. You assume they will give information technology back to you lot if you ever asking information technology. Y'all assume they won't employ it for other customers. Call up again!

- The supplier tells yous they are moving their mill to a new location. You call up it is like moving an office to a new building. At best, it is a serious disruption, causing their production to slow down significantly for 1 or 2 months (and that'southward really optimistic). At worst, the factory is closing and they are subcontracting your production to a 10-person workshop in a garage, with no follow-up of quality.

Note that ane should not generalize these observations.

Non all China-based manufacturers are unethical and incompetent — though many certainly are. Some are very skilful… and very decorated, which means they are less likely to be interested in a small project requiring a lot of engineering science work.

If you assume at that place is a loftier chance that a random supplier you encounter is risky, y'all will accept more precautions. That's the right state of mind when operating in China.

And, to reduce this type of risk, the get-go step is to place the type of "ideal supplier" y'all need to find. This brings me to the adjacent point.

Element of solution 1:

Ascertain an informed strategy and a realistic programme

Importers who are learning how to manufacture a product in Mainland china excitedly beginning devising their new product concept in a bustle to see it become reality, and at the same fourth dimension they're afraid of competitors getting to market before them. Is this yous?

Beware of the 'entrepreneur in a hurry' syndrome. As I wrote higher up, you are about to explore quasi-uncharted territory. You need to gather some information commencement about what is expecting you. Don't rush and find yourself in problem you lot could (should) have avoided.

Remember about all aspects and implications of your product design

What causes the most delays? Fixing issues too late in the procedure. Issues are 10 times more expensive in both coin and time if y'all catch them in the middle of prototyping rather than in initial design, or in product rather than in prototyping.

Here are a few examples of important considerations that are often skipped early, at great cost:

- Do yous crave a level of finishing like to Apple's products? Don't pick a manufacturer that works mostly for Walmart.

- Volition retail packages be stacked up? It means packaging needs to exist strong enough.

- Will users expect the batteries to recharge fully in nether 1 hour? This will have implications on the charger, the type of battery, etc.

- Will users expect to be able to replace parts? Y'all demand to make this operation easy and think of potential safety issues.

Spend some time planning your next steps

Keep Dwight Eisenhower's famous quote 'plans are useless, merely planning is 'indispensable' in listen.

Have you lot been thinking of the different steps of your projection, all the way to "the first batch has been manufactured and shipped out of People's republic of china"?

People with no prior feel in product development systematically underestimate the time and effort needed. Here are two examples:

- Electronic pattern experts will tell you that at least iii prototypes (for both the enclosure and electronics) will be needed. And each iteration takes time.

- If it is of import that your product does non neglect too early in the easily of its users, y'all volition need to run highly accelerated lifetime testing (HALT). It is an actress cost, and you may need to wait for the results earlier confirming the product design.

This is why, terminal year, nosotros suggested a roadmap for complex hardware products that are developed and fabricated in Mainland china. It is not exactly optimistic, but it will become you thinking nigh what yous might exercise right or wrong (and that's the whole point). Work with people who accept done information technology before, in gild to adjust this plan to your specific situation.

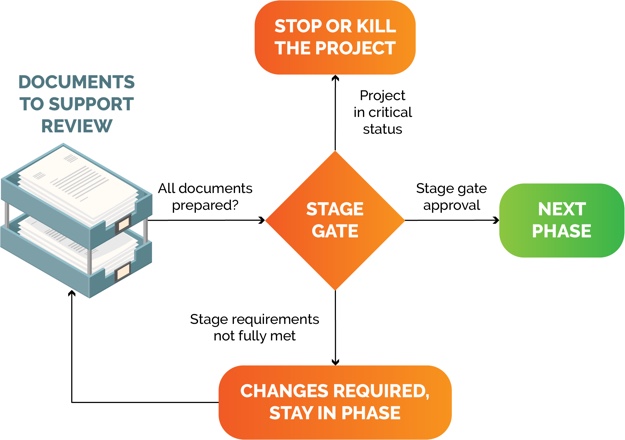

Any milestones?

In your plan for how to manufacture a product in People's republic of china, you volition probably want to include milestones, and ideally a stage-gate blessing process (to do a review earlier moving on to the next phase).

Annotation: this is mutual in established organizations and in certain startups that need to convince investors; it is usually not handled this formally in near newly-formed companies.

Here are examples of classic milestones:

- Confirm the industrial design (i.e. outside appearance of the production) is highly-seasoned to typical consumers (and/or retailers), earlier working on detailed 3D

- CAD drawings

- Confirm a look-akin prototype is appealing to typical consumers (and/or retailers)

- Ostend a 'proof of concept' prototype successfully performs 2 cadre functions

- Confirm a work-alike prototype meets desired specifications

- Get a third-party product certification to establish compliance with relevant regulations

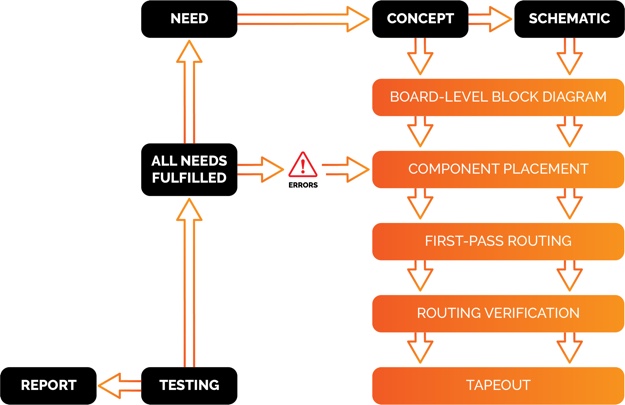

Example: how consumer electronics companies plan for new product introduction

In the consumer electronics concern, new products are the lifeblood of companies. In the USA, especially on the W Coast, they have divers that activity with relatively precise codes.

Hither is a video overview of their new product introduction process:

Wait some delays

Information technology is a sad reality that most projects are delivered late. And, the more circuitous the projection, the more than they tend to autumn behind schedule. Many studies have shown this to be true.

We showed a typical instance (where the project actually took twice as long as planned) in this article. Psychologists telephone call this tendency the 'planning fallacy'. You volition probably not escape information technology.

Take information technology into account when you lot prepare your financial projections — every fixed expense such as monthly salaries volition make your overall costs balloon. Paying fees for services rendered, rather than employing total-time people, usually de-risks the projection in that sense.

In that location are often solutions to save time… merely they might come with high risks

Here are a few examples of time-saving moves:

If you are unsure about compliance, you can do laboratory tests on the components, earlier product, and wait for the results. Or you can have a chance go direct in product.

Doing a pocket-size pilot run before mass production is very useful to catch whatsoever problems in the process and sometimes as well in incoming components. Yous and the factory might decide to go direct in mass production, with the risk of generating much rework, scrapped textile, and aircraft delays.

Your prototypes may contain parts from untested suppliers. Searching and qualifying skilful suppliers tin can take fourth dimension. Once again, yous and the manufactory might determine to have the risk of quality bug on the components of the first batch.

I hope you have read the commencement of this article. The "3 deadly mistakes" I mentioned in a higher place are the pitfalls y'all absolutely need to avoid when learning how to manufacture a production in Communist china.

You also demand to know what the biggest risks, and assumptions, are in your project. Hither are two examples.

- If you presume a particular technology can be used for the purpose yous have in mind, and if that is quite uncertain, the very first thing to do is a proof of concept to accost this assumption.

- If y'all come across the risk of being copied as the highest adventure, talk to a lawyer who works on intellectual property rights and is familiar with the Chinese business concern environment, before y'all talk to anybody else of your product idea. On the other hand, if you lot visit ten companies in Shenzhen without telling them what you lot need to make, that would be very unproductive.

In item, spend some time reducing the market place risk

As consultant Eric P Rose advises hardware startups, you lot should brand certain there is a demand for your production, and you should understand the nuances of that demand before you invest a lot of money and energy in making that product a reality.

Enquiry has shown that 42% of startups that neglect, fail considering they evangelize something the market does not value. That's really the number 1 reason for startup failure!

In improver to market inquiry, one way to keep the marketplace hazard express is by developing a "minimum feasible product" equally version 1.0 of your product:

- Show virtual (computer designs merely), concrete 'look-alike', and physical 'piece of work-akin' prototypes to your target users/buyers, to go feedback along the way and pivot if necessary

- Become to market faster with a simpler product, get real-life feedback, and brand informed decisions most what should be in version 1.1… or 2.0!

What certifications will exist needed in the countries of sale?

Y'all demand to know this from the get-go, and that may crave a bit of research (with a service such as ComplianceGate.com, ProductIP.com, or others).

For case, many of the electronic products we take developed for our American clients require an FCC, and sometimes also a UL, certification. This has to be planned from the initial design stage:

- Placing components the wrong style on a PCB tin cause a failure for FCC (doing blueprint reviews & simulations has proven invaluable, in our experience);

- If you develop a power bank and retailers asking that it is UL-certified, you are probably ameliorate off spending some fourth dimension looking for a bombardment supplier that has already got that aforementioned UL certification.

- The certification needs to be done on pre-production prototypes afterwards the tooling and almost all the engineering work has been washed. Redesigns at that stage can exist expensive and fourth dimension-consuming.

What blazon of factory should you work with?

A business learning how to manufacture a product in China needs to look for the type of supplier that will be a good fit for its needs. I way of categorizing suppliers is based on their business model:

- Original Design Manufacturer (ODM) — if you lot want to piggy-back on their existing engineering, keep investment low, and exist more of a distributor than the product owner. Information technology comes with its own risks.

- Original Equipment Manufacturer (OEM) — if y'all don't mind working in the "Chinese fashion" where the supplier hides some elements only subsidizes the product evolution. The OEM is specialized in the type of production you are buying.

- Contract Manufacturer (CM) — if you are ready to pay for the development and the tooling, and have a clear contract that gives you a lot of control and visibility. The assembler is more than of a generalist, often working on different production categories.

Some other way is past their size. I generally classify them into 3 broad levels:

Smaller factories might be 'light' on engineering science resources and on quality command. Larger organizations tend to be much slower and more expensive. Finding the 'best match' might take some work.

What is the about advisable procedure for prototyping custom-designed parts (if any)? Conventional CNC machining, 3D printing, or more seldom used approaches such equally stereolithography, selective light amplification by stimulated emission of radiation sintering, or vacuum casting?

This information can bulldoze your search for the best partner for initial prototyping. Typical Chinese factories ordinarily don't accept such processes in house, simply can help with afterward-stage prototypes. We'll discuss this in more detail in 'Chemical element of solution 4'.

Chemical element of solution two:

Structure your supply chain on a solid foundation

Your new electro-mechanical product may count tens of components. In many cases, what makes or breaks a development project is a succession of mistakes when setting up the supply concatenation. Here is how to avoid that.

(Past the mode, if you want to get deeper into this topic, I take written e-books on how to discover and develop suppliers, and on how to verify suppliers.)

Identify, screen, and authorize suppliers

By at present you have an platonic supplier type. There are probably thousands of options in your product category, so you demand to screen them downwards.

Start, brand certain yous are not dealing with a trading company pretending to own & operate a manufactory. A business concern registration cheque is simple and quick, and information technology can help you weed these out.

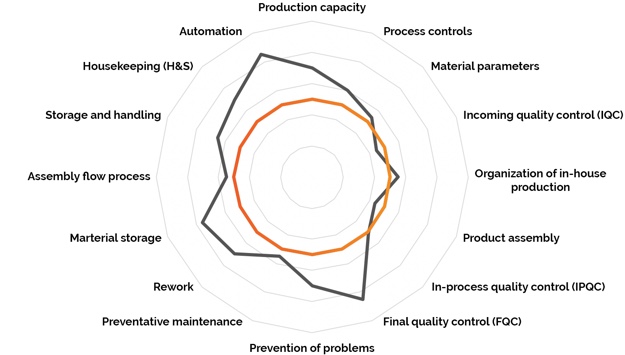

You also need to brand sure they can do a proficient job when the time comes to ramp product volumes upward. Exercise a process audit on one or two central factories. An engineer tin can visit them and look for risks in the most important areas.

In-depth conversations, too every bit astute observations, are also important. If the possessor used to be a salesperson and has been re-investing his profits in real estate, these are usually not proficient signs.

Never allow a middleman obscure visibility

Don't let an assembly factory prepare upward and "own" your entire supply chain. (We cover this in more depth in the side by side section.) If you lot practise not know where the critical components come from, information technology volition cause several issues in the mid-to-long run:

- If there are quality problems in one of the component suppliers, they might never be well resolved, and you won't exist able to send a skilful engineer there.

- Y'all will have lilliputian idea of the margin made by your assembler. We have seen cases where it was in the 60% to 80% range.

- The assembler might raise prices and/or under-evangelize, and you might have trouble rebuilding that supply chain. For example, yous really want to go along the aforementioned anodizing upshot on your production's surface, merely about anodizing workshops can't reproduce it.

Don't effort to control every aspect of your supply concatenation

Some suppliers are critical, others aren't. Yous don't have unlimited resources. Allow your manufacturer choice the suppliers of screws, connectors, etc.

Still, y'all need to identify a few disquisitional lines in the Bill of Materials (BOM):

- If a material is in contact with food, you lot will need to ensure its supplier is aware of regulatory requirements,

- If the casing is fabricated of injection-molded plastic, you lot need that factory to exist capable of delivering consistent quality,

- If gum is involved and might create serious issues, you will need the MSDS.

Have a backup for every critical supplier

This may non be possible when you develop your product and at the time of the starting time gild. You need to call up nearly it at some indicate, though.

It can also be useful if your order volumes option upwardly faster than expected — that's a adept trouble to have, just notwithstanding, a problem if your principal supplier cannot follow every bit apace equally needed.

Keep in mind that onboarding a new supplier takes time. If you look until you need a backup, you might lose a lot of time.

Element of solution 3:

Set up the right expectations from the start

One of the 3 key mistakes I outlined at the start of this guide on how to manufacture a product in People's republic of china is the failure to set a proper understanding from the start with suppliers. It is actually more complicated than that since in that location is more than than 1 document to prepare.

Also, documents and legal agreements are not sufficient. You volition need to adopt the right strategy and make the right decisions.

Clarifying your needs and your standard

Outset things first. Communicate your needs clearly! No Chinese supplier will exist able to guess what your product users need or require, equally well every bit y'all practice.

Start drafting a product specification sheet (including tolerances wherever possible). It will be very useful at all levels — for engineers working on prototypes, for purchasers, for the manufacturing staff, and for all the inspectors along the process.

Once a look-alike and a works-alike epitome is approved, it must be catalogued as part of your standard. Once a pre-production prototype (with parts coming off the tooling made for product) is approved, it will become the new standard. And so on.

Strategies for maintaining confidentiality

In one case your product is on the market and is successful, it is likely to be copied by Chinese companies (whether it is made in Mainland china or non) and fighting them might be very difficult. Before that, though, there are ways to reduce the risk of being copied. Here are 4 classic strategies.

Have a lawyer typhoon a non-disclosure, non-use, and non-circumvention (NNN) understanding that is applicable in a Chinese court, and have every Chinese supplier sign information technology before y'all disclose anything confidential to them.

When you contact and screen potential suppliers, bear witness them a office or product that is dissimilar from yours but requires like processes. Then, only show your product to the 1 or 2 'all-time fits'.

Brand sure to check your potential suppliers on these ii dimensions:

- Nature of business organization: are they a trading company that will necessarily send your IP to outside factories? Once information technology is sent outside of their arrangement, in that location is normally no way to control it.

- Internal engineering competencies: can they work on design & engineering themselves, or will they need to collaborate with outside parties?

Avoid raising money on Kickstarter and Indiegogo besides early in your project, because some unscrupulous companies might even re-use the photos yous prepared as part of their marketing materials!

Compartmentalizing the supply chain (the 'black box' concept)

In Communist china, some buyers accept had a especially nasty surprise: a bad actor in their ain supply chain noticed the product'due south success and decided to take advantage of it by making actress quantities and selling in competing channels.

It is peculiarly destructive because they might beat you lot to the market when you develop your version 2.0 if they take sufficient data about it.

In order to avoid this situation downwardly the road, nosotros have ready this approach for several clients:

- We buy components from various suppliers, who are never given the total picture and don't even know what the terminate product does, in what distribution channels it is sold, what make information technology is sold under, etc.

- We manage concluding assembly (including testing & packing) and shipping, and every party involved is kept in the dark.

Development & manufacturing agreement(s)

Companies learning how to industry a product in Communist china who choose to develop a new production with their new supplier very often forget to specify their requirements in these two areas:

i. Open BoM (Pecker of Materials) — A good BoM includes the full list of the parts making your product, the names & contact data of all the suppliers of these parts, the price of each function, the MOQ and atomic number 82 time to club each part, and then on and and then forth. Read the China Police force Blog'due south take on this.

ii. All the intellectual property generated in the class of this project should exist yours, and all deliverables should immediately be sent to you lot. Equally our favorite lawyers wrote:

"Chinese manufacturers usually adopt to cover all of the costs of production development because they desire to own the resulting product and foreign companies far too often proceed with this, without realizing this likely ways the Chinese manufacturer volition cease up with the production and its related IP."

Negotiating all this is unremarkably straightforward when working with a contract manufacturer, might be difficult with an OEM, and is always very convoluted (or outright impossible) with an ODM.

Quality verification & validation plan for prototypes

If no testing plan is documented for your product, how will the engineers working on prototypes be able to know if they have washed a good job?

For case, yous'll want to test your prototypes:

- For compliance (safety, battery cells…)

- For operation, including stress testing

- For robustness

- For all important features

(As you lot document this plan, and equally you update it, make sure its content ends upwardly in the specification sheet we mentioned above.)

Pushing the product to its limits

Yous are too advised to programme for functional testing outside of 'normal' use.

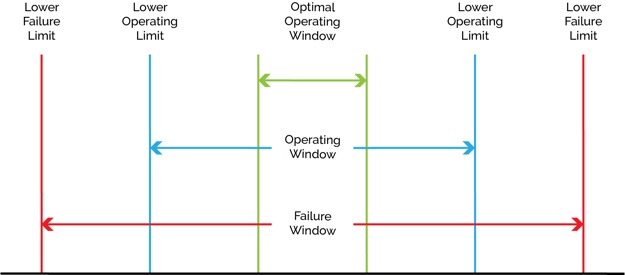

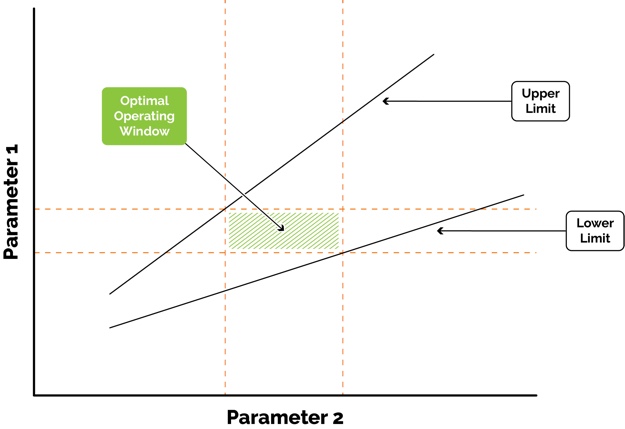

For example, we worked on the development of a battery-powered skateboard. We did tests on smoothen roads, but also on dirt roads, on slopes, with a very heavy user, and so forth. Basically, don't limit yourself to the optimal operating window (shown in green below):

The same logic tin can be applied by a reliability testing laboratory. You don't have to set all this up by yourself.

All the results you gather this fashion volition inform yous of the limits of the product as it is designed. And you might decide on design improvements.

Tooling and other non-recurring engineering (NRE) investments

Spend time planning before giving the dark-green light on these types of investments. Buyers tend to trust their suppliers way likewise much at this point.

For case, for plastic injection molding, how many shots will the mold allow yous to brand? The blazon of steel used will make a large difference — for instance, a mold made in P20 steel might start to require a lot of rework subsequently xl,000 shots, while H13 steel might be proficient for ane million shots.

The harder, and more durable, steel is harder to machine. The tooling takes more time and is more costly. Only it might be merely what you demand. You need to understand and specify all this.

Airplane pilot runs before mass product

I have already mentioned this, but it is worth repeating:

- Some of the components are custom-made — accept these components' suppliers exercise a small batch and count how many pieces are 'good the first fourth dimension'. If the proportion is nether xc%, yous are exposed to abrupt and sudden price increases.

- Your product is new for the assembly workshop, too. Ideally, they take prepared some custom tooling for associates and for testing. A small run on the assembly lines is the all-time way to confirm the processes are ready. The more complicated and new the product is, the more issues will exist discovered this mode.

Quality monitoring of production

You approved a epitome, you feel the R&D engineers know what you want… but what almost the production and quality staff? Exist there if you can during the get-go mass production batch. Notice their ain quality command processes.

Now, do non remember inspectors will prepare all your issues. They simply detect bug — ideally at the source, simply often hours or days later. The key, once your calibration volumes up, will be having the manufacturer fix and fine-melody the right process controls.

When the time comes for the 2nd or third batch, practise not look the production ramp-upwards to be shine. With Chinese assemblers, there are often long delays, equally I described before.

Element of solution iv:

Get the design and engineering right

Let's say y'all followed all the advice I laid out in a higher place because you want to know how to industry a production in China successfully. You lot have a strong plan and a skillful idea of what to do. You lot have found and qualified the right suppliers. You have clarified all the right requirements and got written agreements.

You still need to go on command of technical aspects. Getting competent and experienced people focused on your project and working on the right things is not easy.

Don't go to a Chinese manufacturer too early on

Some people don't spend sufficient fourth dimension working on their product design, and they mitt an immature design to a manufacturer. This is usually misguided for a few reasons:

- A manufacturer makes money when it purchases materials, transforms them (in a 'mass-production' batch), ships them out, and gets paid. Wait them to proceed their all-time people busy with those activities.

- Chinese companies tend to live in the short term. You might exist able to "sell" your project to them and go a few good engineers working on your new product development, but they might be reassigned to other pressing issues 3 months later after you sent a long list of improvements needed on their second prototype. After that, the project might crawl to a halt, or keep going at a glacial pace.

- They are experts at operational procurement and manufacturing, and they are generally weak at evaluating what materials would make the almost sense, sourcing new suppliers, and so on. It means they will non provide all the assistance yous need to make a neat production or simply to fix the issues you run into.

In other words, work with a pattern firm and with a supply chain management firm until you are at the signal where you tin bring a mature design to a manufacturer. It volition be faster and they will requite you better piece of work quality. (And there is a cost for it, plainly.)

Piece of work with people who have already washed information technology before

Your product is unique. It comes with its own challenges. Don't work with engineers who are trying to figure out how to use CAD software, or what protocols to apply, otherwise design & evolution volition drag on for a long fourth dimension!

There is usually a logical process to follow (case below).

PCB logical design process

Designers and engineers should exist able to explain information technology to yous. If they tin can't give you examples of like projects, besides equally the usual steps to follow, information technology is a sign that you are well-nigh to work with the wrong people.

DFM (Blueprint for Manufacturing)

The more unique your product, the more than vital good DFM suggestions volition be for entrepreneurs and SMES who're wondering how to manufacture a product in Red china. Any improvements washed at the design stage will take much less time and coin than in subsequent stages.

A part of this analysis can be reduced to a checklist — here are a few examples:

- Can we reduce the number of components?

- Tin can nosotros observe means to simplify the pattern and cut costs?

- Can we make associates easier, so as to meliorate both efficiency and quality?

- What materials would be the most appropriate?

- How to miniaturize sure elements?

In improver, a adept designer or engineer can review your production blueprint and will usually accept a number of questions and remarks, simply by pulling from their past experiences interacting with Chinese manufacturers.

Foreclose design-related defects

Most quality issues found in the field come either from pattern or manufacturing. Poor blueprint can cause many problems that might merely appear after 6 or 12 months of use.

The more than robust the design is, the less probable you are to experience quality issues down the road. But what makes a robust design? Information technology just means it will be more forgiving of variations in the manufacturing conditions, and defects volition be less probable to appear.

Let'south say a critical operation relies on a concrete and/or chemical process. There is e'er an optimal operating window (in light-green below). For example, the parameters might be pressure and temperature, in an injection molding printing.

If the optimal operating window is tiny, small-scale variations (which might be unavoidable) volition outcome in quality problems. And, if the manufacturer identifies this phenomenon, they will not accept responsibility when you come up dorsum to them with customer complaints.

Manufacturing and testing processes

You lot need to pattern your product, give it shape (prototypes), and test it. At the same fourth dimension, someone also needs to start designing the process and testing information technology.

We have seen buyers button their manufacturers to hurry upward, to the signal where they started assembling products without having thought of the associates steps, without training operators, and without preparing whatever inspection/testing process. These are the cases where everything goes wrong, and shipments stop upwards being very tardily.

How to avoid being in such a bustle that important training steps are skipped? Start to work on information technology at the same time the last prototypes are being validated and the tooling is made. It takes a chip of planning and coordination, merely it is worth the extra work.

These are just a few of the many considerations you need to keep in mind when it comes to the design and engineering science piece of work, which will shape the terminal production'southward toll, quality, and success in the market. In one case once more, make sure to work with experienced people and allocate the correct resources.

![How To Manufacture A Product In China [Importer's Guide] conclusion How To Manufacture A Product In China [Importer's Guide] conclusion](https://qualityinspection.org/wp-content/uploads/2020/01/img-11.jpg)

Conclusion

Many people who come to us asking about how to manufacture a product in China are worried, and they say "new product evolution is messy, and we never know where it is going". I will say this is very truthful if y'all don't piece of work difficult on planning and if you place an untested manufacturer in charge of all the development work.

Your product is new, and you will have to handle associated risks (technical choices, marketplace acceptance…). Make certain you don't add extra risks to the mix.

Three years from now, when you have successfully brought your innovative product to market and you are working on its 2nd (or tertiary) version, you will need to repeat this procedure. You will probably make up one's mind to simplify certain aspects of the pattern and spend more technology fourth dimension in i crucial area. You will probably take measures to preclude certain risks, and spend fourth dimension planning your next steps. You lot might fifty-fifty switch to a more suitable type of factory.

Ideally, y'all will get all this (mostly) right the first time you embark upon a new product manufacturing projection. Information technology was this guide'due south objective. Hang on — it will probably be a long journey. And let me know how it goes.

Source: https://qualityinspection.org/how-to-manufacture-a-product-in-china-guide/

0 Response to "How To Manufacture A Product In China"

Post a Comment